PXI Series

PXI Series

Vibration Series

Vibration Series

-

Three Axis Vibration SensorApplication Scenarios Suitable for various vibration testing needs. 1. High-Impact, Collision, and Modal Analysis: - Widely us...

Three Axis Vibration SensorApplication Scenarios Suitable for various vibration testing needs. 1. High-Impact, Collision, and Modal Analysis: - Widely us... -

Single Axis Vibration SensorApplication Scenarios Featuring excellent anti-interference and high-resolution performance, it can be used for general vibration test...

Single Axis Vibration SensorApplication Scenarios Featuring excellent anti-interference and high-resolution performance, it can be used for general vibration test...

-

Portable Instrument

Portable Instrument

-

Portable Comprehensive Monitoring Test-set for SubstationApplication Can provide Short Term(1-2 weeks) Online monitoring for Transformer/GIS (>10kV). Main Function Locate Partial...

Portable Comprehensive Monitoring Test-set for SubstationApplication Can provide Short Term(1-2 weeks) Online monitoring for Transformer/GIS (>10kV). Main Function Locate Partial...

-

Online Monitoring System

Online Monitoring System

-

Online Comprehensive Monitoring Test-set for SubstationApplication Can provide Online monitoring for Transformer/GIS (>10kV). Main Function Locate Partial Discharge Identify P...

Online Comprehensive Monitoring Test-set for SubstationApplication Can provide Online monitoring for Transformer/GIS (>10kV). Main Function Locate Partial Discharge Identify P...

-

Steel Production Line

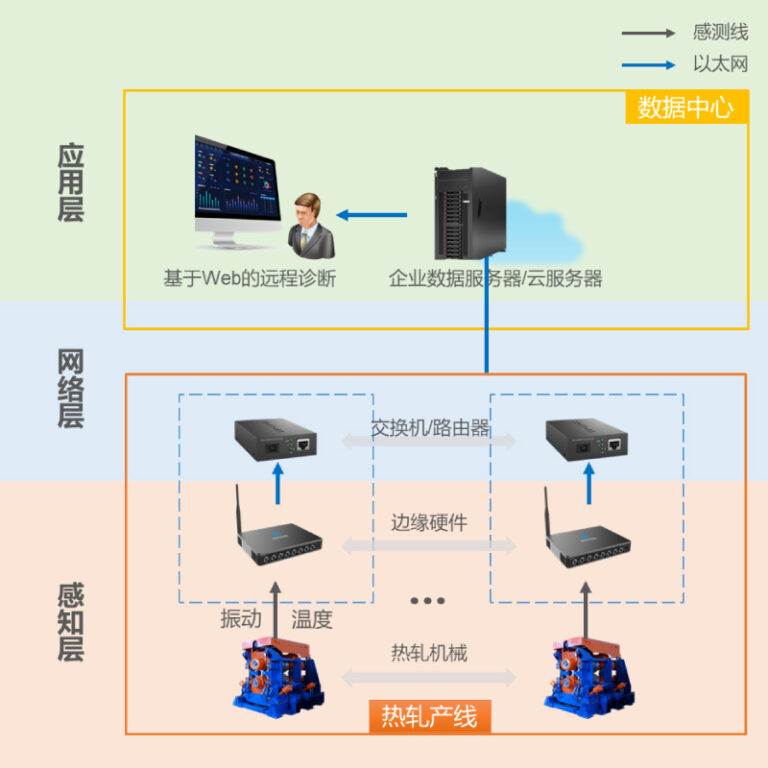

Hot rolling production line intelligent operation and maintenance system

There are many large mechanical equipment in iron and steel enterprises, including rolling mills, motors, blowers, circulation fans, speed reducers, gear boxes, etc. These equipment are key assets in iron and steel production, which are very valuable but usually lack of spare parts reserve. Due to the dynamic operating conditions of heavy load, discontinuous operation, variable working conditions, and the poor working environment of dust and harmful media, these equipment often fail and break down before reaching the expected service life, leading to unplanned shutdowns, forced shutdowns for maintenance, and even major production accidents, which cause huge economic losses to the enterprise.

Pain Point

The iron and steel hot rolling production line is characterized by high automation, complex structure, and harsh operating environment with high temperature, high pressure, and high speed. Once a failure occurs, it can lead to a chain reaction, which can either result in serious damage to the entire equipment, causing huge economic losses, or even endanger the safety of personnel. Therefore, to ensure the safety of equipment and the stability of product quality in the steel hot rolling production line, it is necessary to conduct condition monitoring and fault diagnosis of key equipment. However, most steel companies currently adopt traditional point inspection methods, and equipment maintenance is mainly post-failure and maintenance, lacking effective monitoring of key equipment. Moreover, such inspections mainly rely on visual inspection and sound judgment by maintenance personnel, which heavily depends on individual experience. This not only results in low efficiency and easy to miss inspection and misjudgment, but also poses a threat to the personal safety of on-site maintenance personnel.

Product Features

- Timely grasp the dynamic information of the manufacturing process, equipment, and product quality.

- State information and fault warning information of typical equipment in the hot rolling production line, such as combustion fans, roughing mills, main motor cooling fans, finishing mills, etc.

- Support the identification and diagnosis of typical faults such as misalignment, imbalance, looseness, bearing wear, gear wear, etc.